MILESTONES

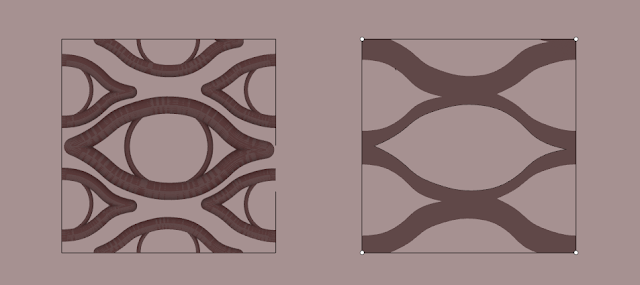

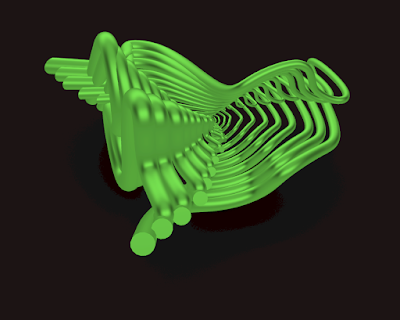

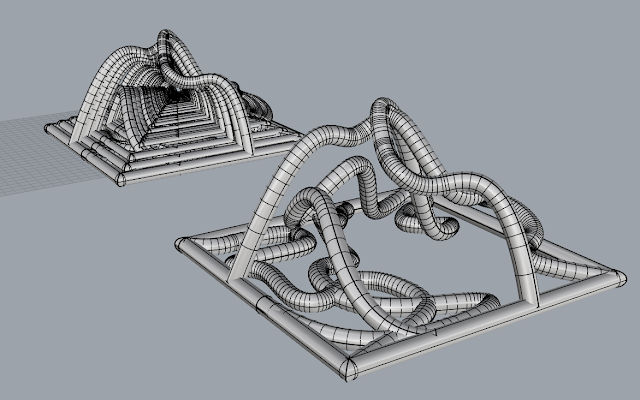

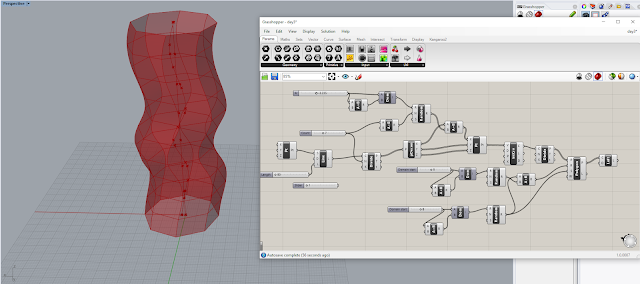

My First Definition Laser Cut Parametric Design Slip Casting A Parametric Vessel Algorithmic Deposition Modelling Jeliane Jeliane Zera Surface Modelling and Animation This semester was a ride. Grasshopper was a challenge because it takes me awhile to get used to the fussiness of it but I also enjoyed it because it makes creating variations of a design easier and faster. Another challenge was learning the 3D clay printer, I haven't gotten to use it which is sad but hopefully students have access learning more of it once this commotion has stopped. In my opinion, I think the biggest success I had this semester was being able to work and collaborate with other people. I was able to talk to few of my colleagues and learned from them. I didn't enjoy the plaster mold project but it is really handy, with what I have learned during those weeks I will apply in making obje...